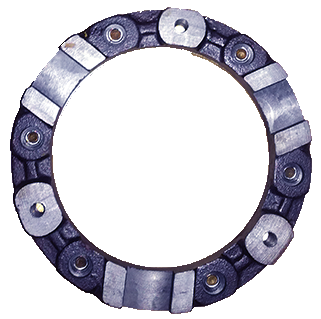

Withdrawal Plate

The withdrawal plate is a versatile tool used in the field of mechanical engineering. Designed to facilitate the removal of bearings and other rotating components from a shaft, it offers a convenient and efficient solution for maintenance and repair tasks.

The withdrawal plate consists of a sturdy, circular plate with a series of evenly spaced holes on its circumference. These holes are strategically positioned to align with the holes on the component being removed, allowing the plate to engage with the shaft and provide a secure grip.

To use the withdrawal plate, the technician inserts bolts through the holes in the component and threads them into the corresponding holes on the plate. The bolts are then tightened, creating a balanced force that evenly pulls the component away from the shaft, dislodging it without causing any damage.

One of the main advantages of using a withdrawal plate is its ability to distribute the pulling force evenly across the component. This ensures that no excessive stress or strain is applied to any particular area, reducing the risk of damage or deformation. Additionally, the plate’s design allows for easy adjustment and positioning, making it suitable for use with various sizes and types of components.

The withdrawal plate is widely used in industries such as automotive, aviation, and heavy machinery. It has become an indispensable tool for technicians and maintenance personnel, enabling them to perform swift and effective removals of bearings, gears, pulleys, and other rotating components.

In conclusion, the withdrawal plate is an invaluable tool in the field of mechanical engineering, providing a safe and efficient method for removing rotating components from shafts. Its versatility, ease of use, and ability to evenly distribute pulling forces make it an essential asset in any maintenance or repair operation.

For More Info feel free to contact us mobile no:+8801736002068

Email: Info@arahmanmew.com

Reviews

There are no reviews yet.